Special Materials and Applications

Sanding machines from Kundig are at home in all areas of woodworking. However, we also supply numerous other industries with our solutions for surface processing. Thanks to our great willingness to develop special solutions and the high flexibility of our engineering department, we have many years of experience in the processing of almost all materials.

Plastics / Composites

With sanding machines from Kundig, plastics of all kinds are processed in hundreds of companies worldwide. These are often fibre reinforced composites, such as glass fibre composites. When calibrating these materials, very precise tolerances can be maintained - even for bottom-top sanding applications and when sanding very large panels. ▶ Video

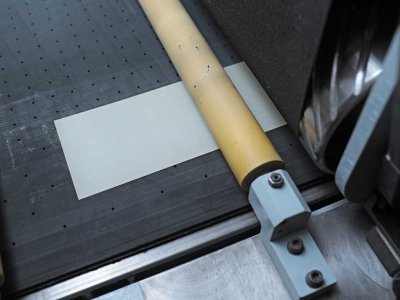

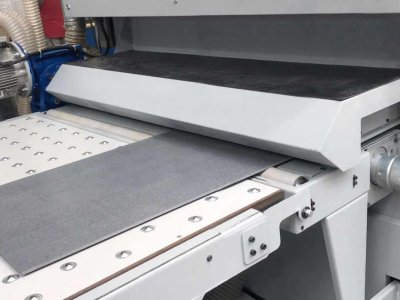

Laminates - HPL and CPL

Laminates are either calibrated to thickness with our sanding machines or roughened for later production steps. Sanding tolerances are in the range of +/- 0.01mm. The requirements for High Pressure Laminates HPL and Continuous Pressure Laminates CPL are the same. With CPL, however, there is the additional requirement that the sanding machine must run absolutely synchronously with the upstream laminate press. Our HPL sanders are available in different versions and thus for all sizes of operation. Our CPL sanding machine model is fully focussed on the requirements of industrial production.

Lightweight materials

- Rigid foams: Sanding machines from Kundig are used in various industries for sanding technical foams. These materials are typically used in the production of sports equipment, the automotive industry and aviation. These thermoset foams are rigid and do not deform during sanding. Therefore they can be measured in a defined way and can be sanded or calibrated with very low thickness tolerances. One challenge are electrostatic charges generated during sanding. Thermoplastics, on the other hand, tend to melt, which must also be taken into account during sanding. ▶ Video 1 ▶ Video 2

- Soft foams: When sanding foam mats, the main challenge is the high flexibility of the material. We have developed methods to take this into account however.

- Honeycomb sandwich panels: On working widths of up to 2200mm, our series Technic-Precision sanding machines can calibrate this honeycomb structure with +/- 0.01mm tolerances. This means that even the most stringent requirements are met, as is common in the aviation industry, for example.

- Carbon fiber: See section below.

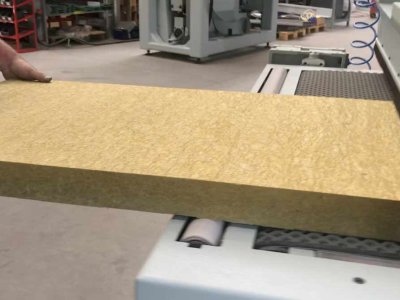

Insulating materials

- Rock wool: Calibrating rock wool or mineral wool usually proves to be quite simple. In fact, our experience in the construction of exhaust systems is needed, as the material tends to wear and clog exhaust components. ▶ Video

- Styrofoam: Polystyrene can be sanded well. The dust is light and can be easily extracted.

- Foam glass gravel: Panels of cellular glass are used for thermal and acoustic insulation. Foam glass can be sanded very well. The main challenge lies in its very high abrasiveness. Our machines can withstand the extreme strain for decades thanks to their special design.

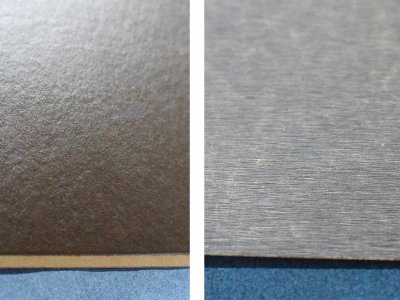

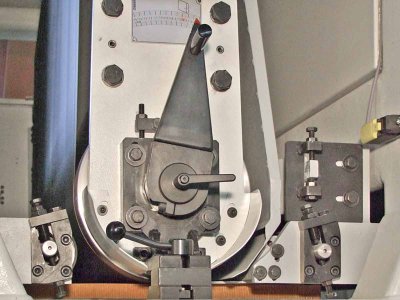

Carbon fiber composite

The lightweight material carbon places high demands on the robustness of the sanding machine and its extraction technology. Using sanding machines from Kundig, the high tolerance requirements of aviation, automotive industry, medical technology and sports equipment manufacturers are met on CFRP (carbon fibre reinforced plastic).

Special case: brake discs: One example of use is one of the leading manufacturers of automotive high-performance brake systems, who uses our wide belt sanders to sand both brake discs and friction linings made of extremely abrasive silicon carbide. This is done at very high throughput rates and with years of use. Aircraft brake discs and clutch friction linings of racing cars are also processed on Kundig sanding machines.

Minerals

- Plasterboards: Gypsum boards can be sanded easily.

- Cement bound particleboard: Cement bound particleboard is also often processed on Kundig sanding machines.

- Acrylic stone: Sanding this material, known under brand names such as Corian or Staron, also works well. As a rule, it is calibrated and then finely sanded with very fine grits of up to 1000 or more to prepare for subsequent polishing or matte-finishing. ▶ Video

Veneer

When sanding veneer, there are a number of applications that require special processing.

- Veneered workpieces: Sanding veneered panels is no problem with modern segmented pad sanding technology and also for cross veneer and changing grain directions there are a number of solutions with our patented oblique sanding technology as well as our cross sanding units to achieve perfect surfaces. ▶ Video

- Veneer sheets: A bigger challenge is the sanding of raw leaf veneer (peeled veneer, sliced veneer, sawn veneer) ▶ Video. Here the precision requirements are very high. We also offer solutions for top-bottom sanding of veneer sheets ▶ Video, as well as for sanding continuous veneer (usually with unwinding and rewinding of spindles before and after the sanding process). ▶ Video

- Veneer edges: Another of our innovations is the sanding of veneer edges. Veneer sheets are stacked and levelled on a special edge sanding machine to obtain one hundred percently right-angled veneer sheets, which guarantees the perfect, seamless jointing of the veneer. ▶ Video

High-gloss lacquer

Of course, sanding machines from Kundig are also suitable for sanding lacquer up to high gloss applications. Thanks to highly developed segmented pad control technology, our patented oblique sanding technology as well as our selection of cross sanding units, our machines are suitable for all applications in this field.

Application example: In the field of high gloss there is probably no more demanding discipline than piano gloss finish. And the highest form of enhancement in this area? Probably the highest quality concert grand pianos in the world. We delivered a Flash lacquer edge sanding machine to just such a manufacturer, as well as a high-gloss wide belt sanding machine with our Hg unit and 1900 mm working width. This enables the mechanical production of a high-gloss effect, which was previously only possible manually and with a great deal of time.

CNC Sanding Technology

CNC sanding technology is another innovation from Kundig. This allows contouring of work pieces with a repeat accuracy and speed that is unattainable with manual sanding or milling. The technology has proven itself in musical instrument construction (e.g. resonance chamber amplification of guitars) and especially in the production of skis and snowboards.

Wood construction applications

The change in quality requirements does not stop at timber construction. A simple planing of visible surfaces is often no longer sufficient. Due to their high stability and solid construction, even the standard version of Kundig sanding machines are well suited for carpentry applications with high loads and have proven themselves over decades. The machine chassis can easily cope with a good 1000 kg workpiece weight and a passage height of up to 500 mm (in special cases even more) allows even the thickest beams or purlins to be sanded. The return function prevents heavy workpieces from having to be lifted out of the machine during several sanding operations by simply reversing the feed. A number of unit options are also available for producing a brushed or rough sawn effect.

Cork

Sanding of cork works very well. An example of application is one of the largest cork product manufacturers, which processes cork underlay webs between 0.5mm and 20mm thick on our wide belt sanding machines. The cork is fed into the machine from a spindle. Winding and unwinding must be perfectly synchronized with the sanding process. The tolerances in this case are +/-0.02mm over a working width of 2200 mm.

Leather

Leather is also processed on Kundig sanding machines. Applications are roughening and calibration. Both single pieces and endless workpieces (winded and unwinded from spindle) can be sanded.

Rubber

We also have experience in sanding rubber. Both endless rubber belts and surfaces can be sanded. For the belts a special tensioning device is necessary, for surfaces we can provide special sanding unit technology. ▶ Video

Non bindingly request your solution

Do you have a particular challenge in processing your surfaces? A special material or a special application? Contact us without any obligation and discuss the matter with our sanding experts.